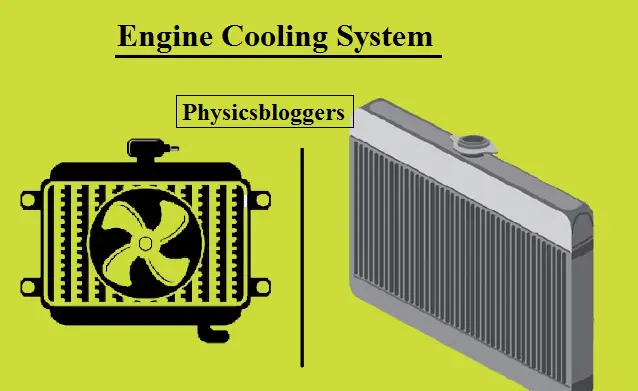

Engine cooling system

Engine cooling system

A motor cooling framework is exceptionally fundamental in vehicles to control the motor’s temperature and forestall overheating. It keeps up with the ideal temperature to stay away from harm due to extreme intensity and advances effective execution.

The essential reason for a motor cooling framework is to eliminate the intensity from the motor and move it into the general climate. This cooling framework contains a mix of parts that cooperate to accomplish it.

History

The historical backdrop of motor cooling frameworks is followed back to improving the gas-powered motor. The main gas-powered motor was created in the nineteenth hundred years. The cooling arrangement of the motor was the premise of air cooling. This motor was straightforward and depended on the encompassing air to scatter heat produced during burning. There were huge balances on the motor chambers to expand the surface region for better intensity dispersal. After that, a more effective cooling framework was required when the motors became more complicated and strong. Toward the beginning of the twentieth hundred years, a fluid cooling framework was introduced and it started with use rather than air cooling. This framework utilizes a fluid coolant, normally water, to retain heat from the motor.

In the next 100 years, radiators and water siphons appeared to work on the proficiency of fluid cooling frameworks. After some time the indoor regulators were integrated into motor cooling frameworks. It stays shut when the motor is cold, permitting it to heat up rapidly, and opens when the motor arrives at the ideal working temperature. The cooling framework became more productive with the advancement of coolants, for example, ethylene glycol-based radiator fluid to further develop execution. In this century electric cooling fans were additionally presented and turned into the piece of cooling framework. Electric fans offered better command over cooling wind current, permitting more exact temperature guidelines and lessening the heap on the motor.

In recent years, motor cooling frameworks have been further developed with PC-controlled indoor regulators. Variable-speed electric fans and coolant temperature sensors are likewise utilized, giving the motor administration frameworks ideal cooling execution.

Why the cooling framework is vital for the motor?

A cooling framework is essential for a motor to control its temperature and forestall overheating. Here are the key justifications for its importance.

Heat Dissemination:

Gas-powered motors create a lot of intensity during the ignition interaction. If this intensity isn’t successfully scattered, it can harm motor parts, including the chamber walls, cylinders, valves, and chamber heads. The cooling framework guarantees that an excessive amount of heat is taken out from these parts, forestalling overheating and potential motor disappointment.

Ideal Working Temperature:

Motors have a predefined scope of working temperatures. The cooling framework keeps up with the motor at the ideal temperature by eliminating heat when essential. This further develops fuel ignition, lessens discharges, and augments power yield.

Oil:

Numerous motors depend on oil for oil. The cooling framework by implication helps in keeping up with appropriate grease by forestalling unreasonable intensity. Over-the-top intensity can separate the oil’s consistency, decreasing its greasing properties. The cooling framework helps safeguard the oil’s adequacy in safeguarding motor parts by directing the motor temperature.

Productive Execution:

A motor works better and is best when it is having at ideal fevers. It supports smoother ignition, expands eco-friendliness, diminishes mileage, and broadens the life expectancy of the motor. The cooling framework assumes an imperative part in accomplishing and keeping up with these ideal working circumstances.

Environment Control:

In vehicles, cooling frameworks likewise add to the solace of the traveler in the traveler compartment. It uses the overabundance of heat from the motor to warm the lodge during chilly climates. The cooling framework utilizes the cooling framework to eliminate heat from the lodge during sweltering climates.

Avoidance of Overheating:

Overheating can cause loss of resistance, twisted chamber heads, and blown gaskets. It can likewise bring about motor seizure, where the moving parts seize because of inordinate intensity and contact. The cooling framework forestalls these issues by guarding the motor temperature inside limits.

Ongoing improvements in the motor cooling framework

As of late the cooling framework is highly evolved and progressed. Some of them are:

Dynamic grille screens:

These screens are additionally important for the ongoing motor cooling framework to improve cooling framework effectiveness in vehicles. These screens essentially open and shut themselves in view of cooling needs. Dynamic grille screens control the framework at higher velocities or under low cooling interest and furthermore, further develop streamlined features and decrease drag.

High-level Materials:

The utilization of cutting-edge materials in cooling framework parts has likewise seen headways. Lightweight and high-strength materials, for example, aluminum combinations and composite materials, are utilized to lessen weight and increment productivity. These materials offer superior intensity move properties, consumption obstruction, and sturdiness.

Incorporated Cooling Frameworks:

A few current vehicles are moving towards incorporated cooling frameworks, where the motor and transmission share a typical cooling circuit. This coordinated plan considers more effective intensity moves between the two parts, bringing about superior general cooling execution and decreased energy misfortune.

These new advancements intend to work on the productivity, dependability, and execution of motor cooling frameworks. They center around better control, streamlined cooling, decreased power utilization, and improved strength to fulfill the needs of progressively progressed and proficient motors.